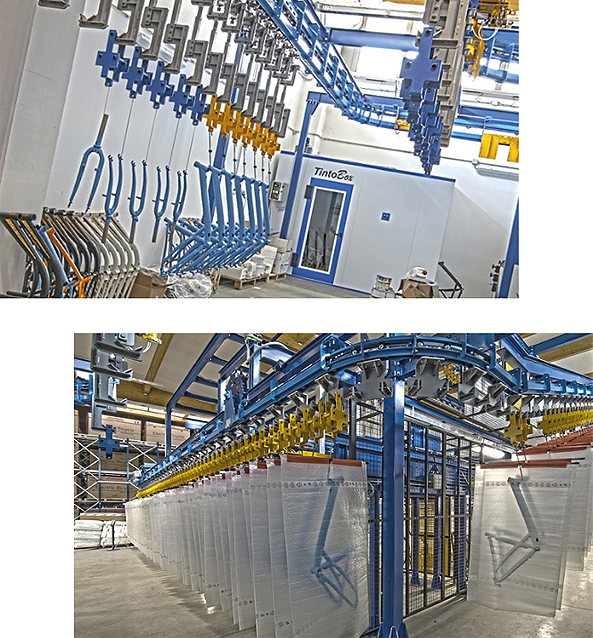

Growing means evolving, looking ahead and making strategic choices capable of creating something great. The joint venture was born in this spirit FIVE-Garelli. FIVE is the most important and technological Italian company specialized in the production of e-bikes. All new collections Garelli are produced in the Bologna factory, each production phase takes place in a cutting-edge structure: design, painting, battery production, assembly, testing. The assembly line, the storage of raw frame components and the painting system are integrated into a single rotary system which guarantees total quality control in every production phase.

Green mobility was born in a company 100% green

In the Bologna factory the integration between nature and production is total. Our factory productive represents excellence in industrial context because it is a building that does not need other sources of energy if not the one that self-produces through a double photovoltaic system.

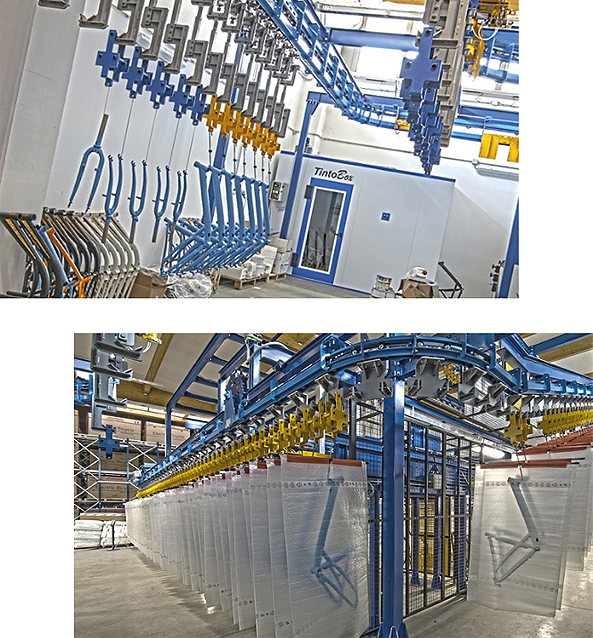

Water-based painting plant

We put people and nature first. We have decided to respect the environment in which we live and work, for this reason our painting system is strictly water-based. Furthermore, always with the aim of minimizing our impact environmentally, the energy used in painting ovens is recovered through a heat exchanger for the benefit of winter heating.

Italian energy

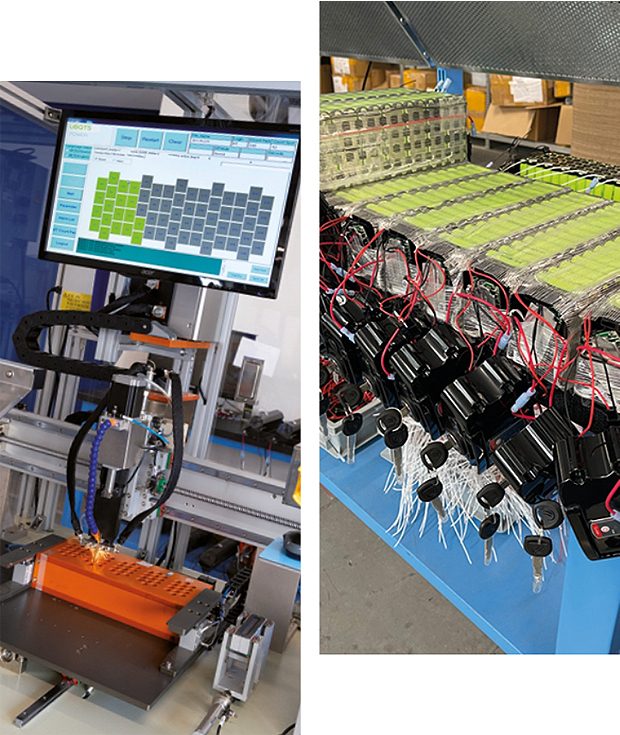

We choosed to produce our batteries in Italy. The batteries of our e-bikes are produced in our own line semi-automatic production. This choice was dictated by the need to guarantee high quality standards and turnaround times planned production. The batteries mounted on our e-bikes are certified according to the UN38.3 standard which includes numerous tests (altitudinal, thermal, of vibration, impact, overload, etc.) which are decisive for guarantee maximum performances and high safety standards.

Italian energy

We have chosen to produce our batteries in Italy. The batteries of our e-bikes are produced in our own line semi-automatic production. This choice was dictated by the need to guarantee high quality standards and turnaround times planned production. The batteries mounted on our e-bikes are certified according to the UN38.3 standard which includes numerous tests (altitudinal, thermal, of vibration, impact, overload, etc.) which are decisive for guarantee maximum performances and high safety standards.

Excellence comes from research

The research and development department is the strategic center of our brand. Inside this technical department and engineers combine intuitions and studies to create products capable of responding to best meet the demands of comfort, performance and quality from modern bikers. We believe in research and innovation, we believe in mobility capable of improving people’s lives people.

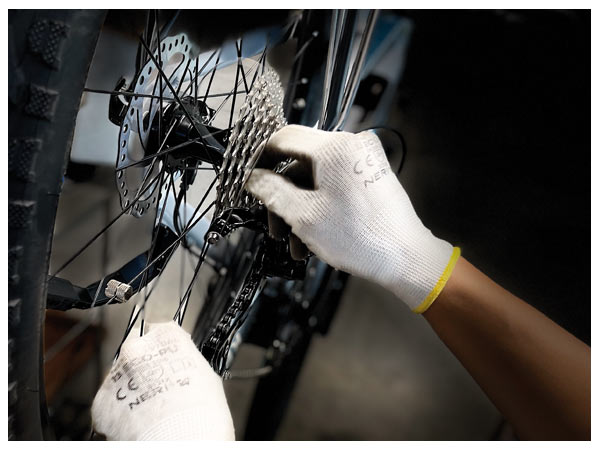

A production of absolute quality

The structured assembly line with 20 stations is equipped with the most advanced systems assembly. This process combined with the expertise of our team of mechanics is a guarantee of construction quality and reliability of our e-bikes over time.